The second byte describes fuel system 2 if it exists and is encoded identically to the first byte. Note that test availability signified by set 1 bit completeness signified by reset 0 bit. The second, third, and fourth bytes give information about the availability and completeness of certain on-board tests. Bit A7 the eighth bit of byte A, the first byte indicates whether or not the MIL check engine light is illuminated. The first byte contains two pieces of information. A more elaborate explanation of these data is provided here. Where a? Some of the PIDs in the above table cannot be explained with a simple formula.

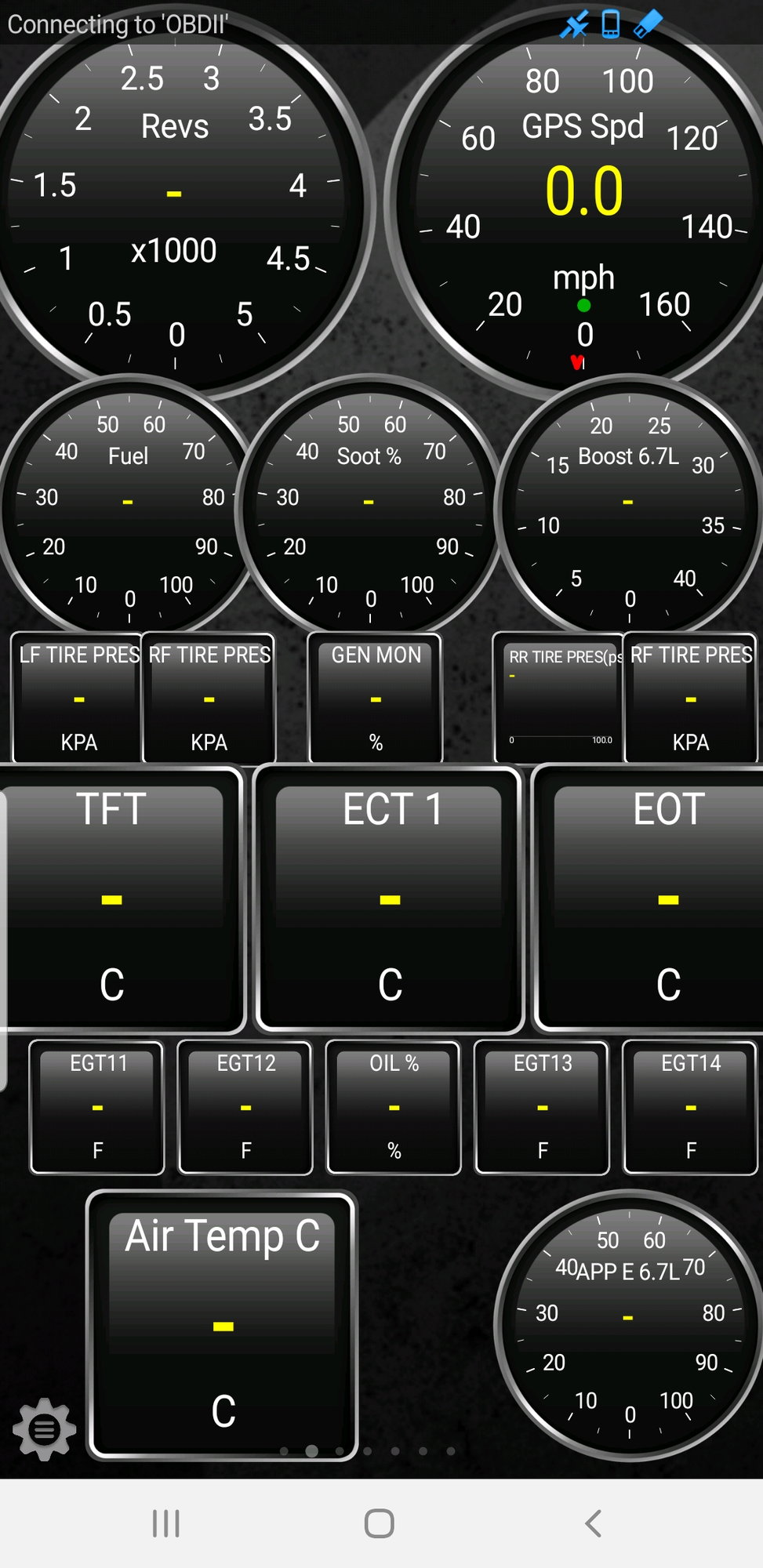

In the formula column, letters A, B, C, etc. PID 0圆0] 01 41 4 Monitor status this drive cycle Bit encoded. Note that modes 1 and 2 are basically identical, except that Mode 1 provides current information, whereas Mode 2 provides a snapshot of the same data taken at the point when the last diagnostic trouble code was set. The expected response for each PID is given, along with information on how to translate the response into meaningful data. My 4.Each manufacturer may define additional modes above 9 e. Here is another PID I also posted elsewhere some time ago. I cannot confirm this PID as I recently discovered my own fan clutch is broken!! Likely has been for the 8 years I have owned it. I have good reason to believe this PID to be F. Next PID up I cannot definitively confirm but maybe someone here can. Without the "01" appended there is a noticeable delay in the initial response time. You can see this using the test button in Torque while connected to your vehicle.

At first look I believe once Torque gets the answer it was seeking it remembers the format for the duration of that session but not further. Then Torque adds the "01" to the end of the PID, as in this case would be B01, and bingo, the PCM answers with the data requested on the first request, speeding up the original startup at least. Torque sends the same request again and is again rejected. I snooped the Class 2 bus while using Torque and found that with the "header" left blank many extended pids fail.

Since that other post I have discovered that if one adds an "01" the the end of these extended PIDs the Torque app will receive the data quicker from the PCM as Torque won't need to cycle through formats seeking an answer from the PCM. I have been spending a great deal of time fiddling with these PIDs of late and have additional informations that I will post on this thread. It is possible that this is my first original post! A short time ago I posted a new pid I discovered for the Fan Speed of a 4. For a better experience, please enable JavaScript in your browser before proceeding. How to create Custom PID in Torque App Current Gear Members Registered members Current visitors.

0 kommentar(er)

0 kommentar(er)